How Mobile Scanning Eliminates Manual Errors in E-commerce

For a lot of fast-growing online shops, mistakes don’t stem from human carelessness. They are embedded in the process.

Items get picked based on memory. Shipping labels get checked visually. Different product variants share almost identical packaging. And in the middle of that, fulfillment speed keeps increasing, especially with same-day delivery expectations.

This is exactly where small errors start to creep in: the wrong item in the box, the wrong quantity, or the wrong label. Those errors are usually not because someone is careless. They’re because the workflow is manual.

Mobile scanning changes that.

Below is a breakdown of where mobile scanning eliminates friction — and how a simple app contributes to fewer returns, happier customers, and more predictable operations.

Where errors hide in manual fulfillment

In an e-commerce operation, there are four places where errors usually occur.

The picking stage

Anybody who’s worked at an e-commerce warehouse can testify that items can look very similar, especially when they’re factory-packed. It’s easy to make a mistake when picking an item based on visual assessment only. For example, picking the right T-shirt but in the wrong size.

The packing stage

It can also happen that while the item was picked correctly, it ends up in the wrong box. Customers are often encouraged to purchase in bulk for the sake of e.g. free shipping or a bigger discount. In that case, many items need to be packed together and it’s easy to misplace an item and put it in the wrong package.

The labeling stage

Shipping labels serve the purpose of marking the package with product and customer details. Labels are usually printed on site, i.e. at the dispatch location. Without a scanning workflow, mistakes can easily happen when a label is applied to the wrong box.

The loading stage

When dealing with multiple packages per customer, it’s easy to mess up the quantity of items. For example, if products are packaged individually and ordered in large quantities, it’s common to load fewer packages than ordered. It can also be the case that the courier loads more items than the customer expects.

All four of these stages share something in common: someone is relying on visual confirmation. And visual confirmation is both slow and ineffective.

Why mobile scanning works so well

Mobile scanning converts these “is this the right item?” moments into a simple check. Either the barcode matches or it doesn’t. That one change does three things operationally.

- Reduces cognitive load – pickers and packers don’t rely on memory, they just follow scanning prompts.

- Creates a digital trail – every decision is backed by a timestamped event.

- Removes ambiguity – there’s no arguing later about where the error happened — the scan data shows it.

This is why mobile scanning has such a strong effect on accuracy even in small teams. Most small e-commerce sellers don’t realise how many returns are self-inflicted by minor packing mistakes. A mobile scanning step always reduces return volume.

If a store eliminates just a handful of incorrect shipments per week, profit margin improves meaningfully.

A scanner in your pocket

In a modern workflow, any smartphone can become a verification device. Instead of the old style handheld terminal, the typical setup is simply a smartphone with a camera-based reader. That’s it.

This is exactly what makes scanning accessible to small operators – any phone becomes a scanner. This way you can verify if:

- the correct item is picked

- the correct quantity is packed

- the correct order is labeled

- the correct parcel is loaded

When a workflow moves from manual identification to scanning confirmation, quality scales without adding headcount. Onboarding new team members also becomes easier because the process is highly replicable.

In other words, mobile scanning turns the previously complicated workflow into a system that anyone can follow. That is why it has such a disproportionately positive effect on last-mile delivery performance.

Best mobile scanner for e-commerce

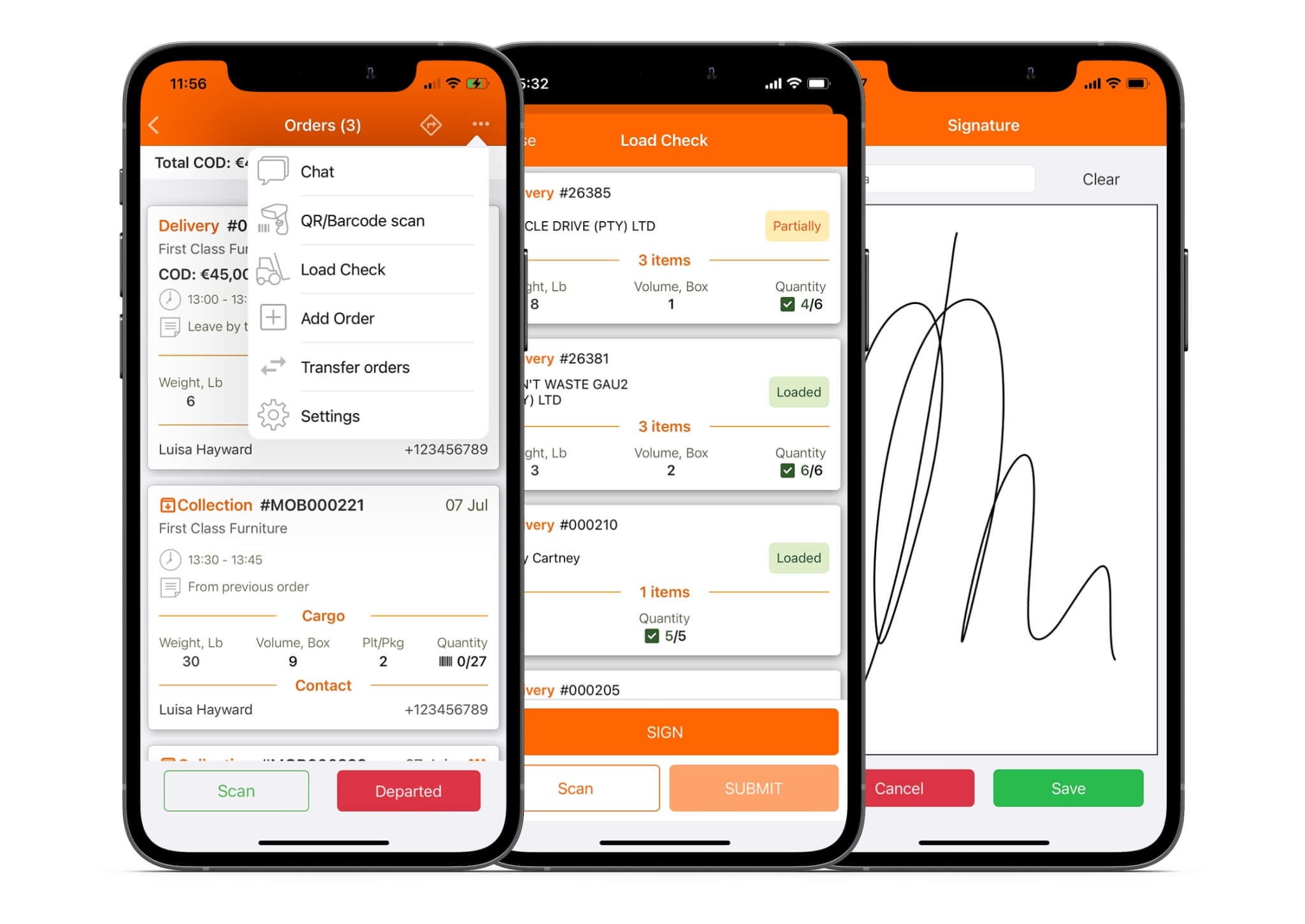

If you’re ready to boost your operations with a smartphone-based scanner, consider Track-POD’s delivery management solution. It’s a platform used by delivery teams to plan routes, assign drivers and collect paperless Proof of Delivery.

Track-POD offers a built-in barcode & QR scanner inside the driver app. That means the phone your courier already uses becomes the scanner. Which empowers any small e-commerce team to eliminate human error without an enterprise budget.

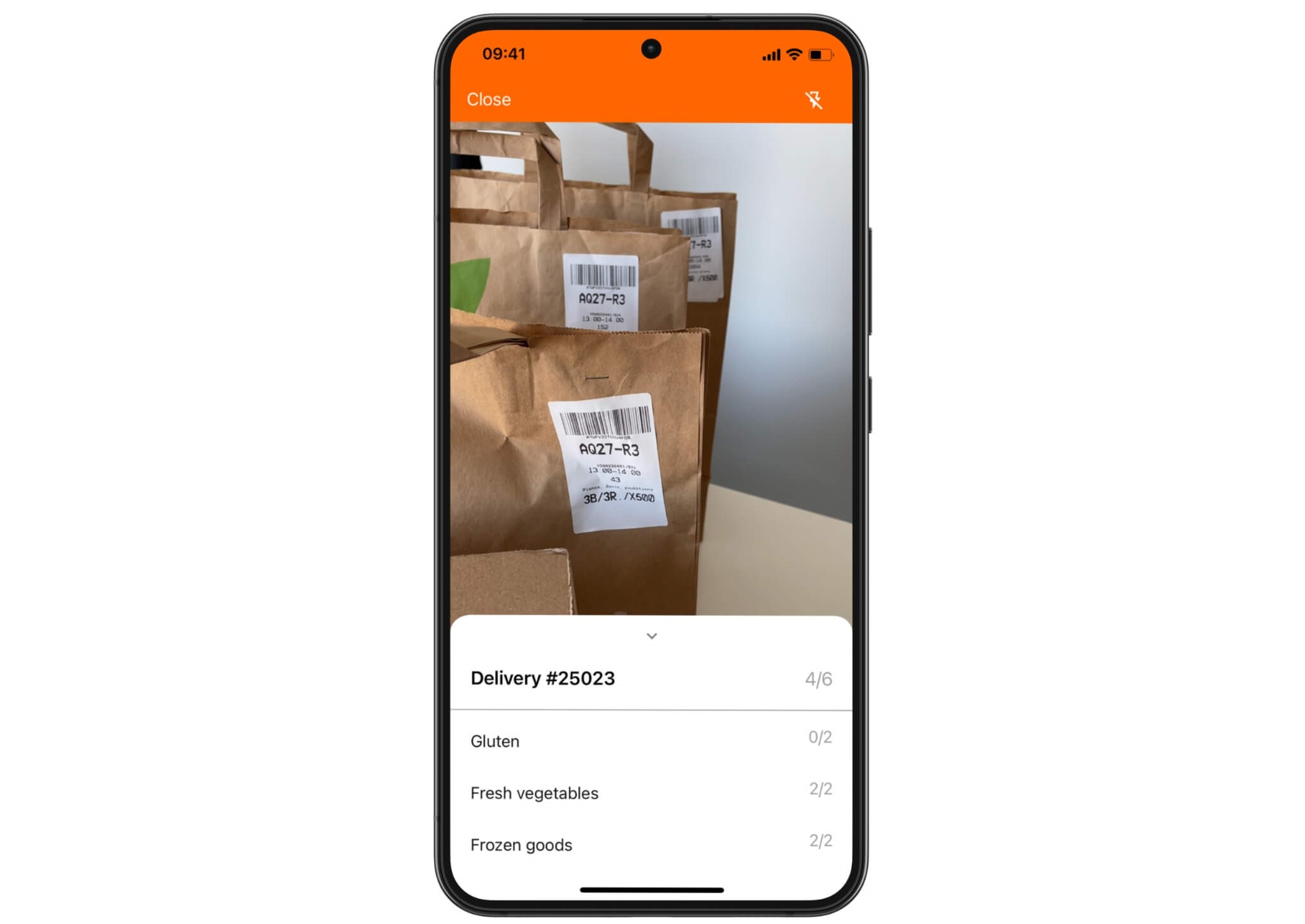

The scanning workflow starts with generating and printing shipping labels from the web dashboard. When the driver opens the Track-POD app on their Android or iOS device, all assigned orders are already there, ready to be scanned.

If the driver scans a barcode not linked to the order, or attempts to re-scan the same item twice, the application shows a warning immediately. The effect of this immediate feedback is that errors are intercepted before a single parcel is loaded incorrectly.

Mobile scanning is not only helpful at the depot. With Track-POD, scanning can also be performed again at the customer’s doorstep, which is especially useful in contactless scenarios. With no customer standing there to visually confirm the parcel, the risk of errors increases. Scanning at drop-off eliminates that risk. The workflow becomes doubly validated: once at the loading stage, once at the delivery site.

Final thoughts

Small e-commerce operations often think that scanning is for big companies. But the most meaningful ROI usually happens before a business becomes large.

Mobile scanning is not a luxury, it’s affordable with the right software and doesn’t require additional investment into hardware scanner devices. It replaces visual validation with automated confirmation, minimizing mistakes and returns.

That’s how mobile scanning eliminates manual errors — and quietly levels up the entire e-commerce workflow.